Filtration is Key to Efficient Environmental Air and Process Cooling Systems

Filtration Systems Can Reduce Maintenance and Downtime

To strike an interesting analogy, a cooling tower and heat exchanger is to a building what the lungs and heart are to the human body; when either aren’t working properly, it effects other parts of the body and your health suffers. Similarly, when a cooling tower and heat exchanger are not clean, the heat exchange process doesn’t work efficiently and the health of the production and process cooling system suffers.

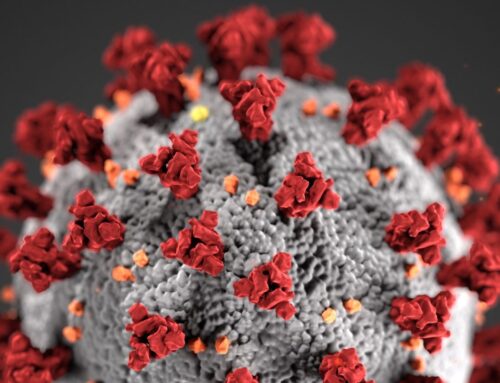

Buildings and production processes that rely on cooling towers to dissipate heat from the cooling water accomplish this by drawing massive volumes of air into the cooling tower as the water travels through the fill material on its way back to the sump. Through the natural evaporative process, heat is dissipated from the water before it reaches the sump from which it is re-circulated through the chiller then through the heat exchanger and back again (kind of like when you perspire while working and letting the air evaporate the perspiration to cool you down). It is important to realize that cooling towers are gigantic air scrubbers that capture all airborne debris that happen to be floating nearby, and if the system doesn’t have effective filtration, the debris can clog the fill and get circulated and trapped in the heat exchanger where it can build-up, restrict water flow and cause their process equipment to malfunction due to overheating.

An example of this is illustrated by a major automotive assembly facility that had faced periodic downtime due to their robotic welding systems not holding temperature tolerances and causing quality problems. After the robotic technicians spent several days trying to initially solve the problem, one of the maintenance workers opened the heat exchanger and discovered that it was impacted with cottonwood seed, insects and other debris – flow had been restricted and the robotic equipment was running hot. Now you may be asking yourself – why didn’t they have some sort of filtration equipment? The answer is simple; at the time the facility was built, the ambient conditions in the area didn’t require a filtration system be used. However, as the years went by and the area became more developed and cottonwood tree populations grew, the need eventually surfaced.

The interesting thing to note about this situation is that even though cleaning the heat exchanger got the robotic welding system back on-line and running at peak performance, it didn’t solve the problem. In fact, cleaning heat exchangers is like taking a cold capsule to relieve the symptoms of a cold. Unless you treat the root cause of the problem, the cooling system will suffer time and again. The root cause in this case and in most heat exchanger fouling situations is the cooling tower – stop the debris from getting into the cooling tower and it will protect the entire cooling system including fill, cooling water, chiller and heat exchanger. With the proper filtration technology the cooling system will stay clean and run efficiently all season long. Selecting The Right Filtration System It is important to realize that optimizing the ecology and operational efficiency of the evaporative cooling system is best accomplished by combining a good water treatment regimen with some type of filtration. The reason is, water treatment specifically targets suspended solids and particulates of 40 microns and below, while filtration systems are effective at stopping larger debris, especially the kind that causes system clogging and fouling.

Selecting The Right Filtration System

It is important to realize that optimizing the ecology and operational efficiency of your customers evaporative cooling system is best accomplished by combining a good water treatment regimen with some type of filtration. The reason is that water treatment specifically targets suspended solids and particulates of 40 microns and below, while filtration systems are effective at stopping larger debris, especially the kind that causes system clogging and fouling. Today, there are two general technologies used in cooling tower filtration: Water Based Systems for which there are a few different variations and Air Intake Filtration Systems. With water-based systems, the choices include basic water strainers that remove debris by passing water through a mesh strainer; sand filtration systems that remove debris by passing the water through sand and centrifugal separators that spin the water and remove the debris through centrifugal action. In contrast, Air Intake Filter Systems remove the debris by filtering the air as it is being drawn into the cooling tower, keeping the debris out of the system before it is entrained. When considering the filtration options, the following questions should be asked:

- What is the cost associated with downtime and lost productivity due to heat exchanger or cooling tower fouling or clogging? (Knowing this will help you justify the cost of filtration to your customer).

- What type of debris is most problematic (can you see it or is it microscopic)?

- Specifically what part of the system does the filter options protect?

- Which system provides the greatest filtration surface area (this can directly impact frequency of cleaning – the smaller the filter the more frequently it needs cleaning).

- Can the filtration system be installed without shutting down the cooling tower? (If the cooling tower must be shut down for installation, your customer will need to factor lost productivity into the cost of the filtration system if it’s not being installed during shutdown periods).

- What is the cost associated with both the filter and installation?

- How easy is the system to install and maintain?

Answering the above questions will help to fully understand the options and make the best choice for the operation. In the case of the automotive manufacturer, the solution they selected was the Air Intake Filter system. The reason was that they needed a system that would protect their entire process cooling system including fill material, cooling water, chiller and heat exchanger. When they evaluated water-based systems, they discovered that the options provided varying degrees of protection for the chiller and heat exchanger but didn’t protect the cooling tower where the root of their problem was. If they had selected a water-based system, their cooling tower would have still drawn airborne debris into both the fill and water where the water filter would have captured the debris before it circulated throughout the system. From a maintenance standpoint, that would have solved the heat exchanger problem but it would have done little to reduce maintenance on the cooling tower. Further, when they compared the cost of water based filtration versus air intake filtration technologies, Air Intake Filtration was found to be the more cost effective approach for their operation.

If the system does not currently use filtration as part of the environmental air and process cooling, then any filtration technology will give more protection than what it now has. However, selecting a solution best suited to the operation requires knowledge of what type of debris is causing the problem and where it is getting into the system. As a rule of thumb, “ don’t select a small debris solution to solve a large debris problem”. Conversely, “don’t select a large debris solution to solve a small debris problem”. There is clearly a place for both water based filtration and air intake filtration – be sure to select the right filtration for the specific need.

If the facility is only looking to protect their chiller and heat exchanger from airborne debris, then one of the water-based filtration technologies can help them manage the debris that gets into the cooling water. If on the other hand, the need is for full cooling system protection, then air intake filtration is the best solution – It will stop the debris from getting into the system in the first place.

Author(s): Randy Simmons, Air Solution Company